Form with Function

Design is as much about purpose as it is about aesthetic. We employ a fine balance of both in each of our pieces. Every project we undertake is as important to us, as it is to our clients. Your vision is produced with an artisan’s touch to assure that no detail goes overlooked, and that your unique style is framed through the experience of the piece.

Details

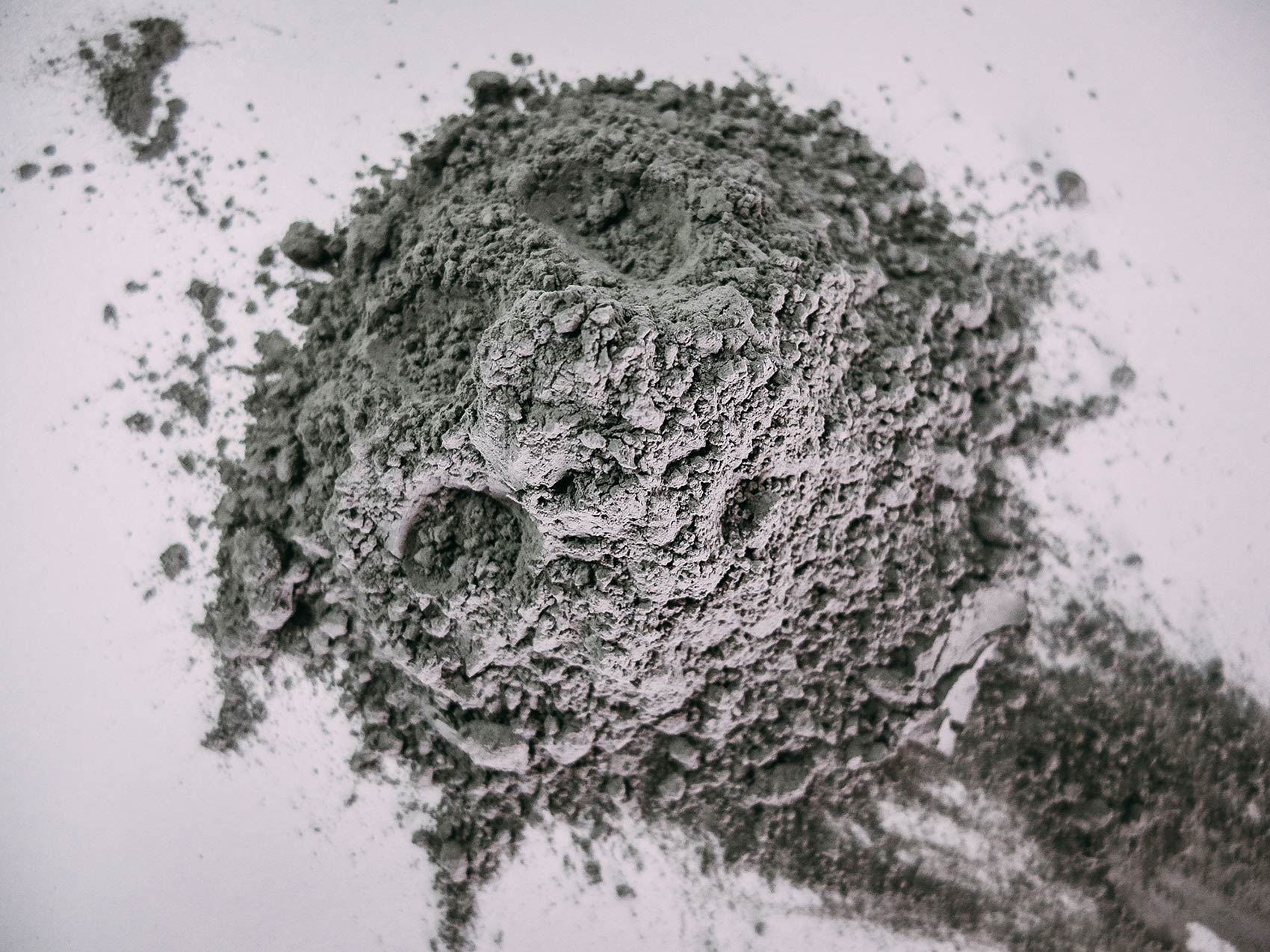

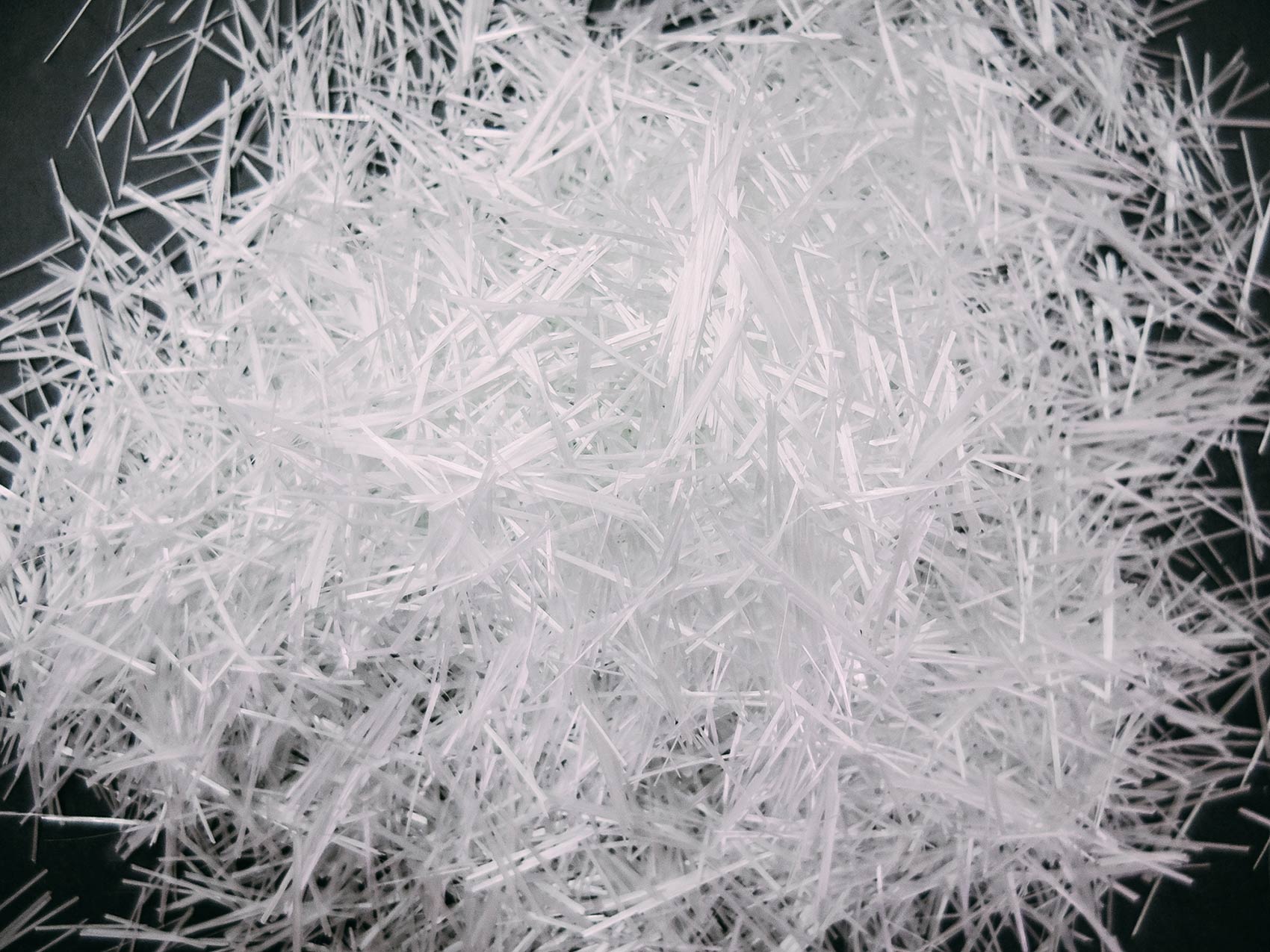

MATERIAL

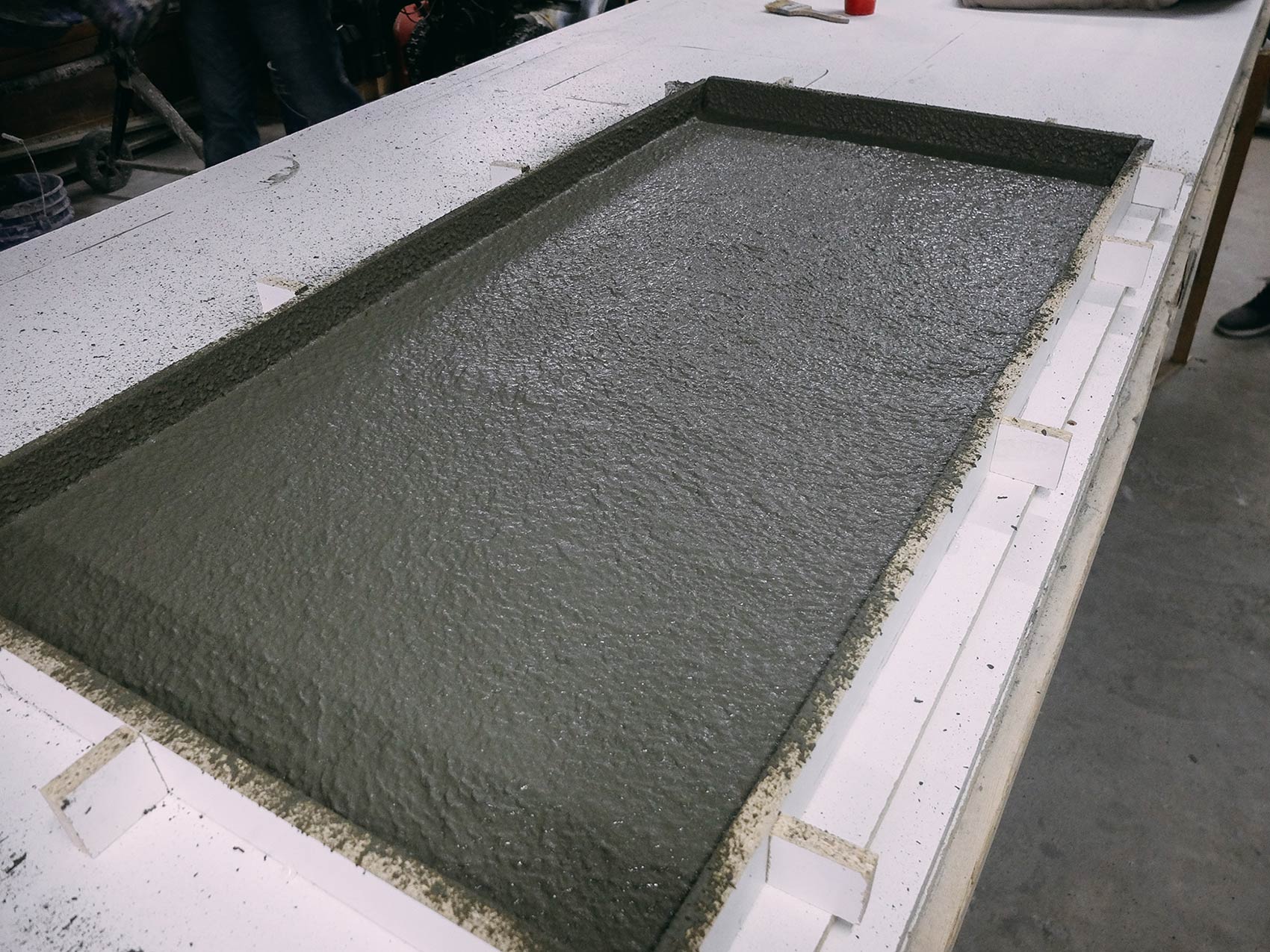

All ANR Concrete Studio pieces are made with glass fiber reinforced concrete (GFRC). The combination of glass fibers, portland cement, sand, and a blend of additives result in a product that is many times stronger than concrete used in conventional applications. Our pieces average 10 lbs per square foot at 1.5” thick. The high strength materials used in ANR pieces optimizes strength to weight ratio to assure that the countertops will not negatively impact the structure of your cabinets. Pieces are sealed with the highest quality food grade sealer. This sealer assures that concrete holds up against staining and etching similar to the performance of granite or marble.

ARTISAN CONCRETE BENEFITS

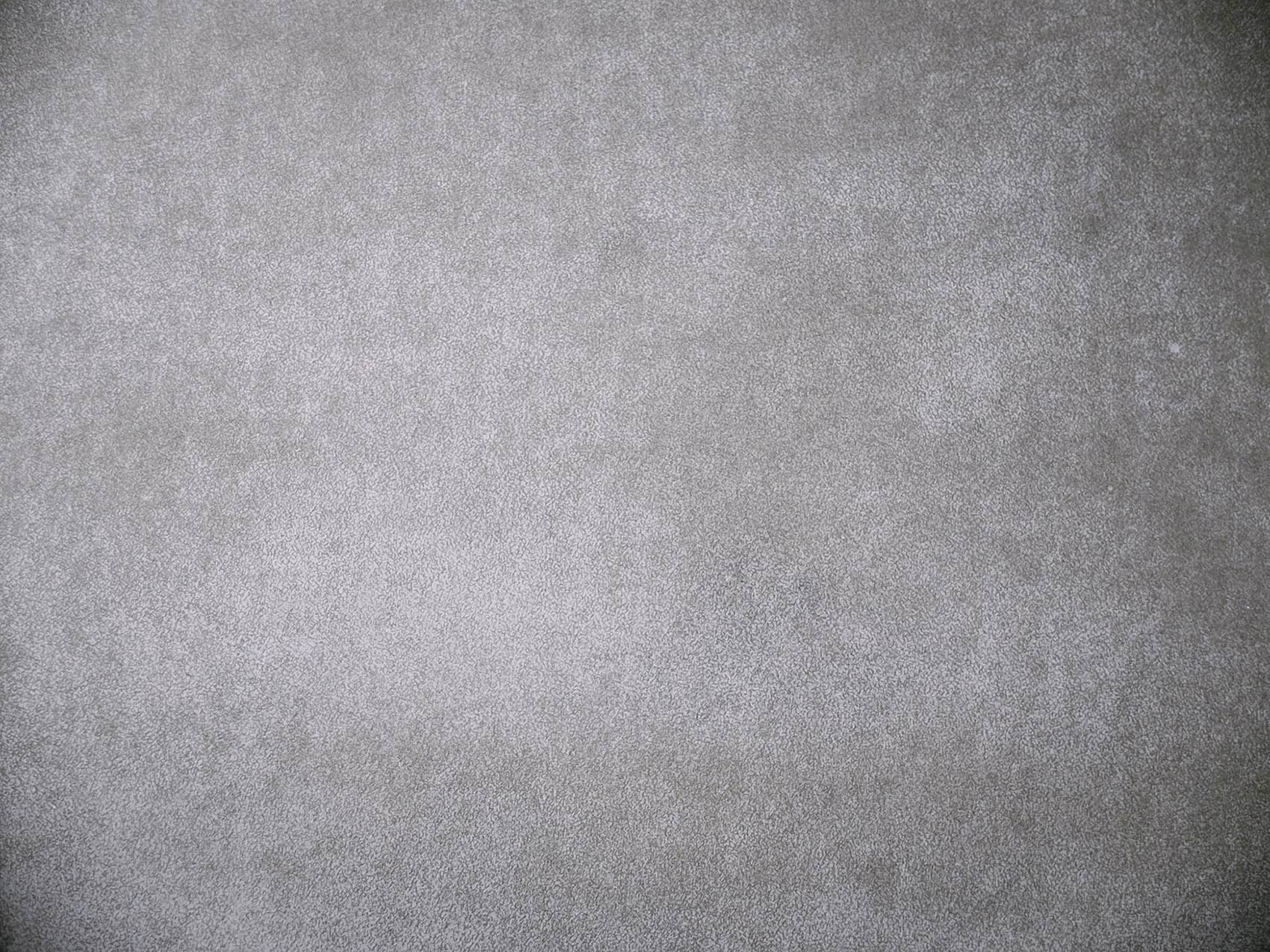

The beauty of the material is in its imperfections. The fluid nature of concrete allows for infinite design potential. The freedom to define shape, color and texture is limited only by your imagination. Color variations, aggregate exposure, marks from tools and forms all add distinct character. Every piece made by ANR is unique, impossible to duplicate and special in its own right. In a world of the 'mass produced', handmade artisan concrete is a refreshing sight and conversation starter for those who are new to the capabilities of the material.

COST

The beauty of working with concrete is the freedom of custom design. This freedom doesn’t lend itself to standardized pricing, rather a custom price to coincide with the design. ANR pricing is competitive with that of most mid-range hard surface countertops. Since the process generates very little waste, cost is optimized, and you pay for only what material is used in your project.

SUSTAINABILITY

Concrete ingredients and aggregates are found in nature. Many are also produced, in part, with recycled materials. All materials used in our products are manufactured in North America. This buying practice reduces our carbon footprint by eliminating transportation of materials from quarries overseas.

Natural

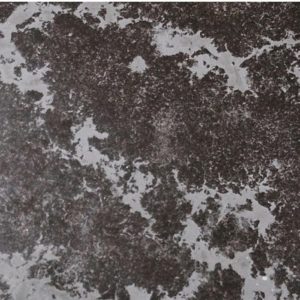

Veining

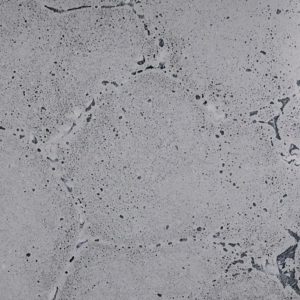

Terrazzo

Color

Process

Template · Forms · Pour · Polish· Seal

Team

Adam Rossetto, the founder of ANR Concrete Studio, has been around concrete and construction in one form or another for over 30 years. Growing up in a construction family, he become familiar with the material and how to work with it in it’s conventional form at an early age. Adam completed his engineering degree, and was later married in 2011. On a trip to California, Adam was introduced to GFRC countertops and furniture. From that day forward, the learning hasn’t stopped! Adam’s passion is creating beautiful and functional concrete products that excite his clients. Adam lives in Lasalle, Ontario, with his wife, two sons and daughter, who enjoy the creations he comes up with almost as much as he does making them!

Andrew Schincariol, and Adam have been friends since childhood. Aside from being lifelong friends, Andrew was one of the original “clients” of ANR, in the infancy of Adam’s adventure with GFRC. Andrew’s concrete countertops have been serving him well since 2011! His belief in the product, and complimentary skill sets to Adam’s made for a natural fit that became the partnership that is ANR Concrete Studio. Andrew is a partner in ANR, lives in Windsor, Ontario, with his wife and two daughters.